5 Tips To Choose the Right Tapered Roller Bearings

What are Tapered Roller Bearings ?

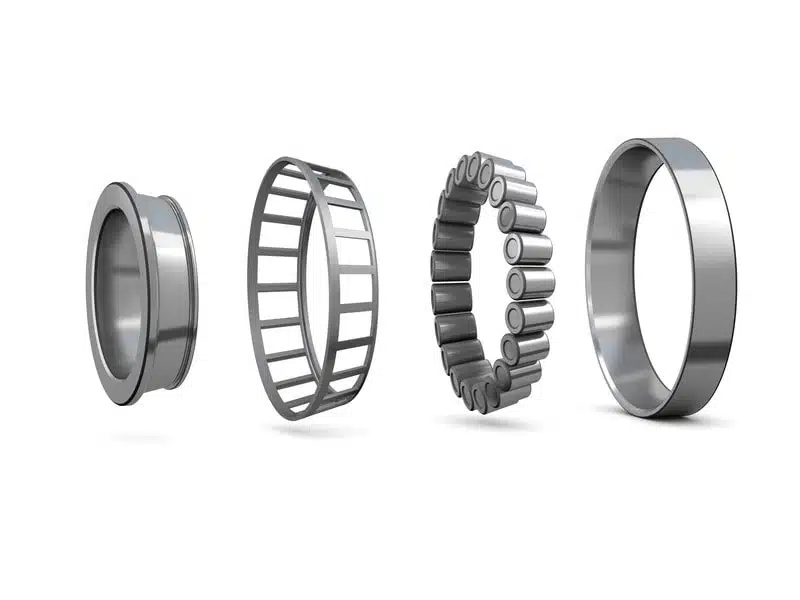

If you want to purchase the tapered roller bearings, you should know what it is. First, a tapered or taper ball bearing has zero clearance. This makes them a good choice for applications where precision is required and sealing of moving parts is paramount.

A tapered roller bearing is a specific kind of ball bearing: a cylindrical rolling-element bearing with tapered outer rings. They are designed so that the inner ring (which is the part that actually rolls) almost always makes contact with the outer ring, making for a very precise and smooth rotation. This is a very important feature in many applications, especially those where precision is required.

The tapered roller bearing also has a low friction coefficient due to its design and materials used, making them ideal for high-performance applications.

Single Row Tapered Roller Bearings (SRTRB) are used in many applications where high load capacity and low friction are required. They are also known as “Roller Bearing” or “Tapered Rollers”.

Finding the right tapered roller bearing isn’t easy – that’s why you need us. Our experts have years of experience in roller bearings and will help you find exactly what you need.

1. The Size Of The Bearings

Taper roller bearings are available in different sizes with respect to the diameter of the bearing ring. These bearings are usually made up of steel and are manufactured using various machining processes such as turning, milling, drilling, etc.

The size range of the tapered roller bearing is determined by the diameter of the ring and the width of its bore. The most common sizes are available in standard, metric and imperial dimensions. You can also get them customized according to your requirements.

2. The Type Of Bearings

There are two main types of tapered roller bearings – plain bearings and deep groove ball bearings. Plain bearings are used in applications where there is no need for high load capacity and low speed rotation. Deep groove ball bearings are used in applications that require higher loads and speeds. The Need For Tapered Roller Bearings SRTRBs are used in applications where there is a need for high load capacity and low speed rotation.

These bearings can be used in the following applications:

-Electric motors and generators

-Traction engines

-Industrial machinery with high loads

3. The Material Used In Making The Bearings

The material used in making the bearing determines its performance. A bearing made with steel will perform better than one made with aluminum. The material also determines the price of the bearing. Steel bearings are more expensive than aluminum ones. The Lubrication System If you don’t lubricate your bearings, they will wear out faster and cause a lot of friction between parts that move against each other. Use grease or oil to keep them from wearing down too quickly.

4. The Number Of Rollers

The number of rollers and their size determine how much load the bearing can handle. Bearings with more rollers and larger diameter rollers can handle higher loads. The load capacity of a bearing is determined by the number of rollers, their diameter and the material they’re made from. The bigger your load, the more rollers you’ll need to support it.

5. The Load Capacity Of The Bearing

Bearings are rated for a certain load capacity, which is the amount of weight they can support before they start to wear out. The higher this rating is, the better; it means that your bearing will last longer under heavy loads. If you’re planning on using the bearing to support a lot of weight (for example, if you’re building something like an industrial crane), consider getting one with a high load capacity rating.

The quality of the bearings is also important. As with all types of machinery, bearings need to be durable and well-made in order to last a long time. Cheap bearings are more likely to break down quickly and require replacement sooner than high-quality ones.

More About EVERGLORY

EVERGLORY is one of China leading bearing manufacturers of tapered roller bearings.

EVERGLORY can make backing bearings and taper bearings such as single row tapered roller bearing, double row tapered roller bearing, 4-row tapered roller bearing and single row cylindrical roller bearing, double row cylindrical roller bearing, four row cylindrical roller bearing, and so on.

With 20 years of experience leading tapered roller bearing manufacturers, EVERGLORY is both manufacturer and exporter. If you have any inquiries about high-precision bearings, please contact us.