1. What is a Sendzimir Mill

The production capacity of cold-rolled steel strips is one of the indicators of a country’s level of steel industry development. Currently, industrialized countries predominantly utilize multi-roll cold rolling mills to produce metal strips of materials such as stainless steel, silicon steel, alloy steel, and more.

The emergence of cold-rolled steel strips can be attributed to the patent invention by Dr. Tadeusz Sendzimir, the father of rolling mills. In 1931, Dr. Sendzimir obtained a patent for the continuous galvanizing method, which still serves as the foundation for galvanizing today.

In 1932, he obtained another patent for the use of small work rolls and a rigid body to cold roll strip steel. The first Z-High mill was used in Poland to roll low-carbon strip steel. In 1933, Dr. Sendzimir invented the 20-roll mill, which could produce highly precise, high-hardness, and high-deformation-resistant thin alloy strips with low energy consumption and high product accuracy.

This technological innovation further propelled productivity, and to honor Dr. Sendzimir as the inventor of such mills, they are commonly referred to as Sendzimir mills.

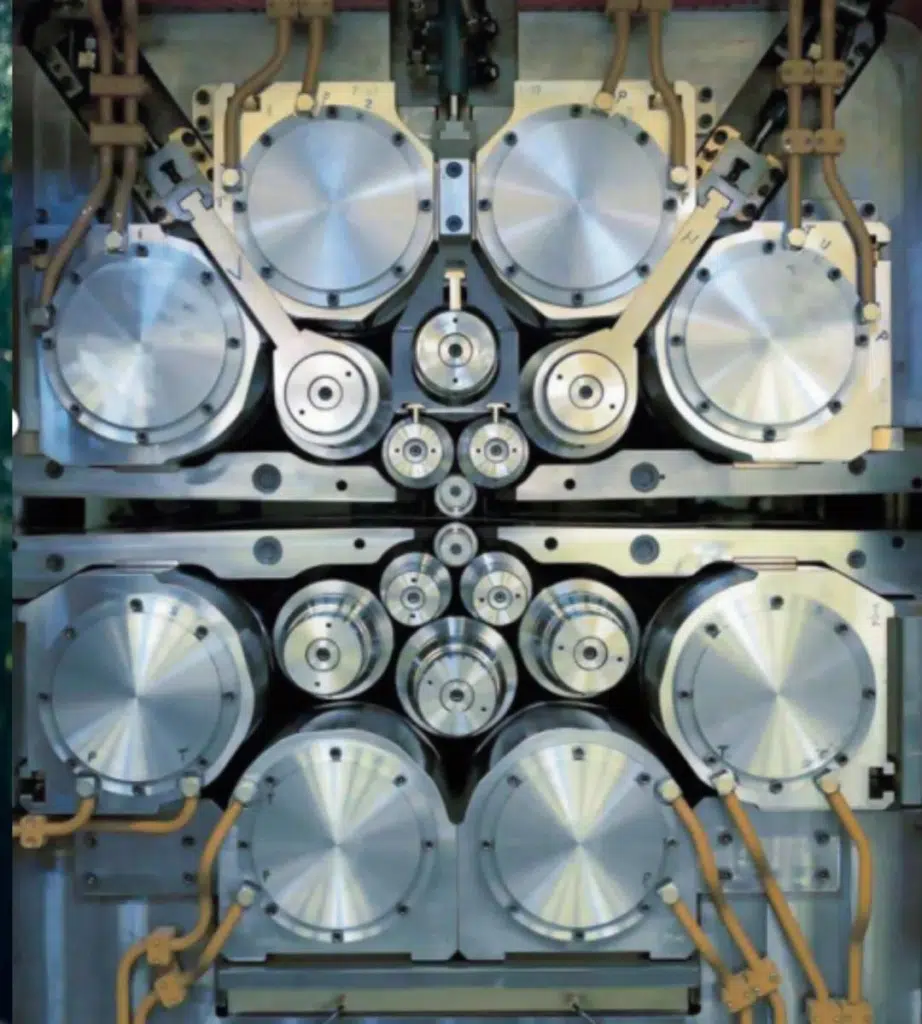

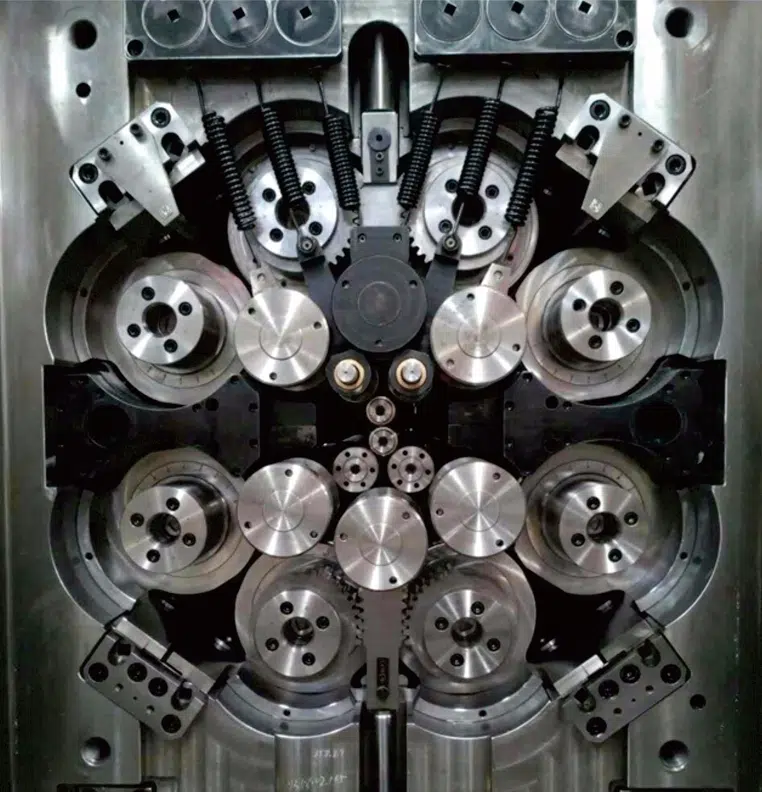

2. What are the Sendzimir mill bearings

Sendzimir mill bearings are mainly used on the support rolls of Sendzimir mills. These bearings require high speed, high load capacity, and high precision, with long usage cycles and intermittent alternating use.

In the design, manufacturing, and testing of Sendzimir mill bearings, EVERGLORY has innovated the design theory and processing technology based on the characteristics of high speed, high load, and high precision operation.

New structural forms and design standards have been established, and the contact ratio between the raceway and the rollers has been optimized. To address the need for high-speed operation, process control methods to prevent bearing heating have been implemented.

The contact surface edge of the outer ring has been optimized to prolong the bearing service life. Additionally, personalized design modifications have been made based on specific operating conditions.

The new structure, new technology, and new design concepts pioneered by EVERGLORY are the first of their kind in the domestic industry. Customers have found that EVERGLORY’s Sendzimir mill bearings not only approach or even reach the level of world-famous brands in terms of service life but also match the precision of world-famous brands’ products.

EVERGLORY’s Sendzimir mill bearings have achieved a substitution for world-famous brands’ bearings. With the successful development of Sendzimir mill bearings, EVERGLORY has established a complete set of design and process standards for Sendzimir mill bearings, filling the gap in the domestic market.

3. What is EVERGLORY’s process manufacturing and control

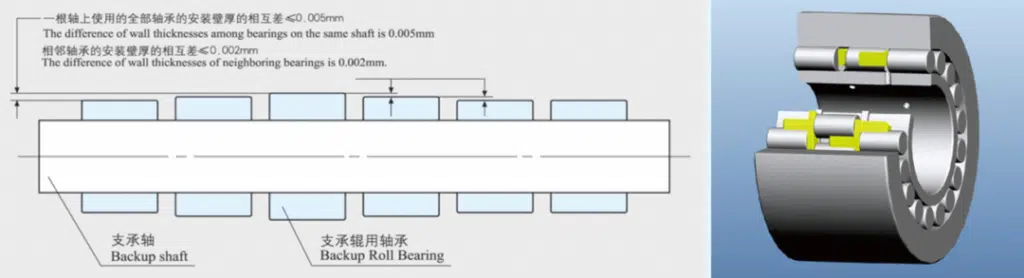

To ensure that the design and operational requirements of Sendzimir mill bearings are met, EVERGLORY maintains strict control over the production and manufacturing process.

Our manufacturing process includes material preparation, forging, turning, heat treatment, grinding, cages, rollers, and other components, assembly, cleaning, oil coating, and packaging.

Whether it is the mutual difference in radial clearance, the difference in wall thickness between the inner and outer rings, or the requirements for grinding allowance on the outer ring, EVERGLORY regulates the manufacturing process information through a rigorous and effective management system.

With the collaborative efforts of experienced engineers and technical personnel, the product undergoes more than 60 meticulous processes to ensure the precision and operational characteristics of EVERGLORY Sendzimir mill bearings, meeting your expectations.

We always remember our mission, to create durable bearings with ingenuity, and provide you with genuine quality assurance.

4. Why Choose EVERGLORY’s Sendzimir Mill Bearings

EVERGLORY is a professional in P4 Backing Bearings, P2 and P4 Sendzimir Mill Bearings, P5 Spherical roller bearing, P5 Taper Roller Bearing, Cylindrical roller bearing, deep groove ball bearing, Crusher bearing, thrust bearing, Split bearing, Precision bearing , and other middle and Large size bearings.

With 20 years of experience leading Sendzimir Mill Bearings manufacturers, EVERGLORY is both a manufacturer and exporter. If you have any inquiries about high-precision bearings, please contact us.