Bearings for continuous caster and bearings for rolling mills.

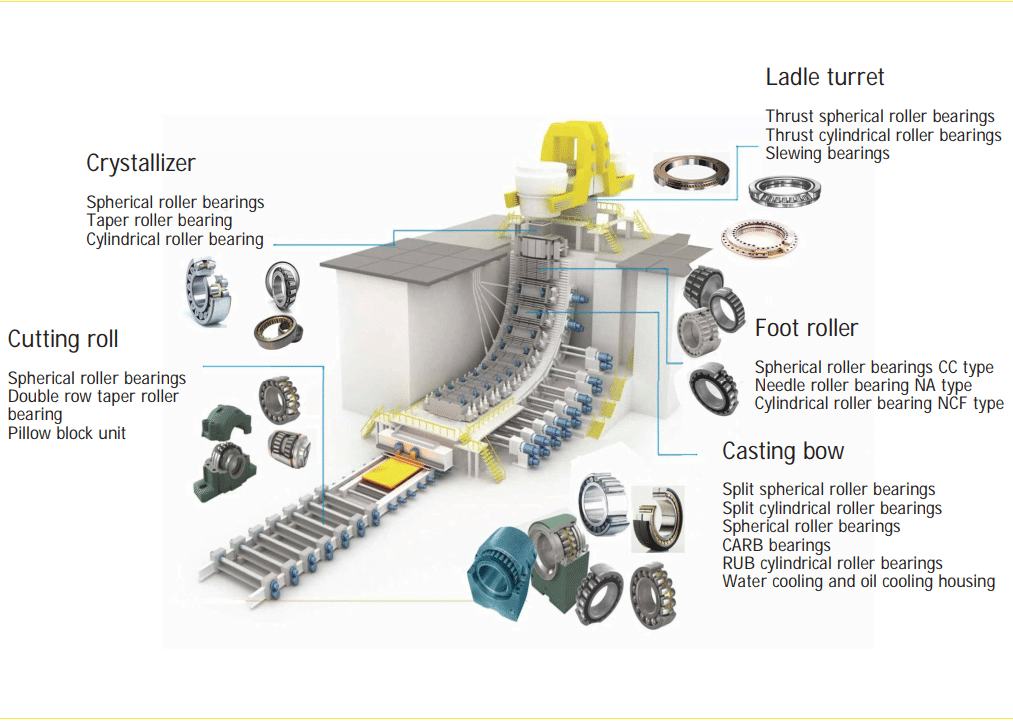

1. Typical bearings types in continuous caster

Crystallizer

Ladle turret

- Spherical Roller Thrust Bearing

- Cylindrical Roller Thrust Bearing

- Slewing Bearings

Foot Roller

- Spherical Roller Bearing CC type

- Needle Bearing NA type

- Cylindrical Roller Bearing NCF type

Casting Bow

- Split Spherical Roller Bearing

- Split Cylindrical Roller Bearing

- Spherical Roller Bearing

- CARB Bearing

- RUB Cylindrical Roller Bearing

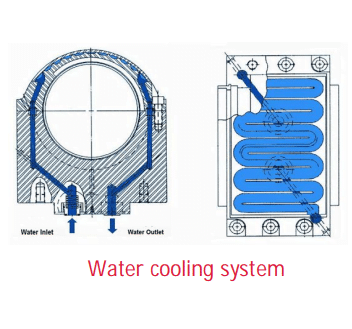

- Water Cooling and Oil Cooling Housing

Cutting Roll

- Spherical Roller Bearings

- Double Row Taper Roller Bearing

- Pillow Block Unit

Typical bearings arrangements for 1600 slab caster

| Equipment | Bearing Number | Dimension | Qty | Part |

| Oscillator | 24044BZD/C4W33 | 220 x 340 x 118 | 8 | mold |

| 23238BZD/C4W33 | 190 x 340 x 120 | 8 | Mold | |

| GE161ES | 160 x 230 x 105 x 80 | 8 | Mold | |

| Segment 1~6 | 24024CA/S1C4LW33 | 120 x 180 x 60 | 144 | Non- drive roll |

| 23220CA/S1C4LW33 | 100 x 180 x 60.3 | 288 | Non- drive roll | |

| 24026CA/S1C4LW33 | 130 x 200 x 69 | 24 | Drive roll | |

| 24122CA/S1C4LW33 | 110 x 180 x 69 | 48 | Drive roll | |

| Segment 7~8 | 24030CA/S1C4LW33 | 150 x 225 x 75 | 48 | Non- drive roll |

| 24026CA/S1C4LW33 | 130 x 200 x 69 | 96 | Non- drive roll | |

| 24030CA/S1C4LW33 | 150 x 225 x 75 | 8 | Drive roll | |

| 24026CA/S1C4LW33 | 130 x 200 x 69 | 16 | Drive roll | |

| Segment 9~10 | 24030CA/S1C4LW33 | 150 x 225 x 75 | 48 | Non- drive roll |

| 24026CA/S1C4LW33 | 130 x 200 x 69 | 96 | Non- drive roll | |

| 24030CA/S1C4LW33 | 150 x 225 x 75 | 8 | Drive roll | |

| 24026CA/S1C4LW33 | 130 x 200 x 69 | 16 | Drive roll | |

| Total | 864 |

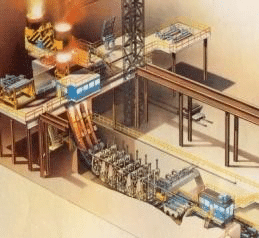

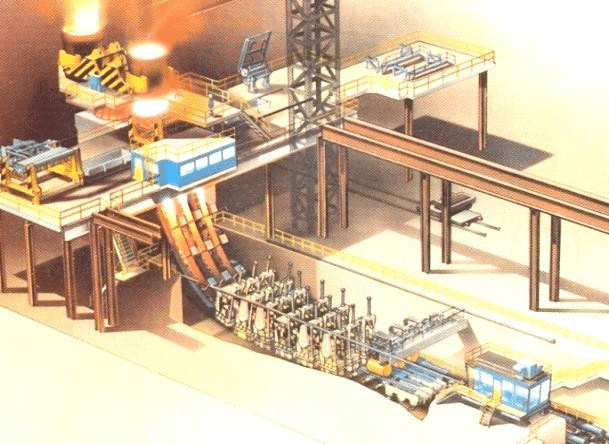

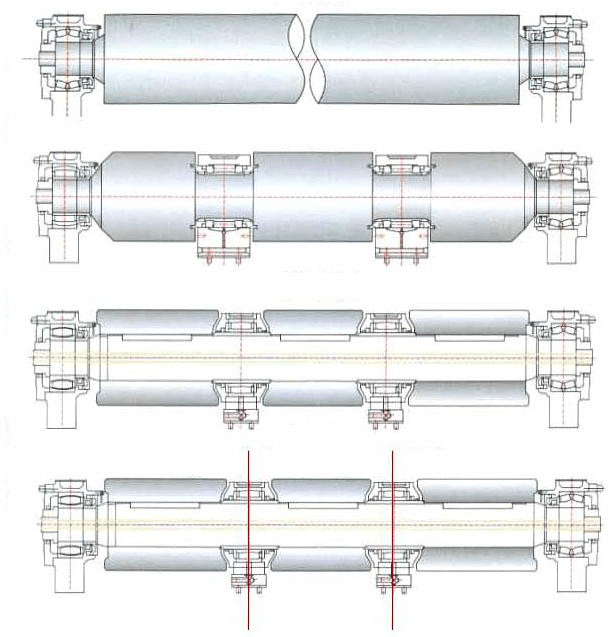

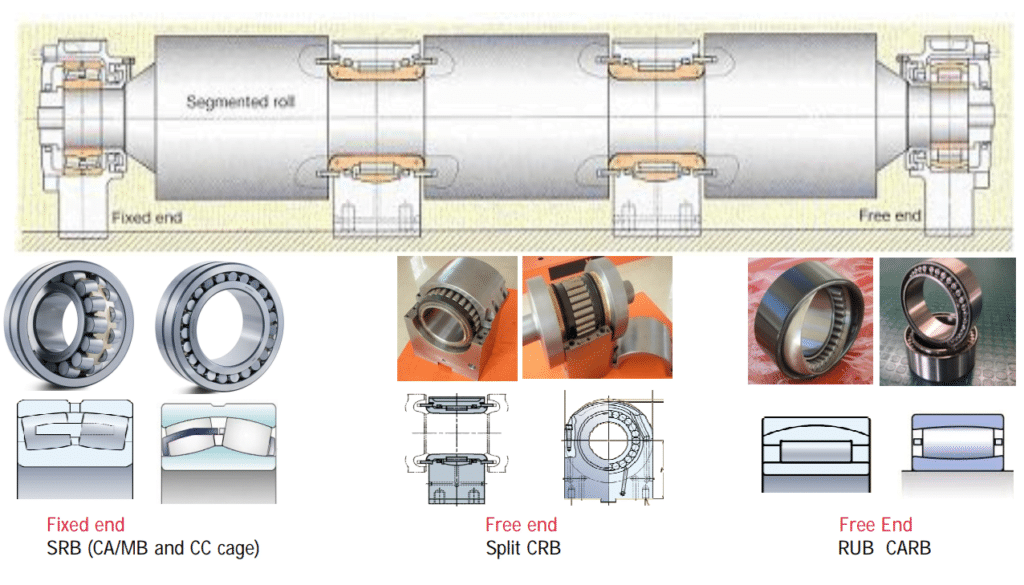

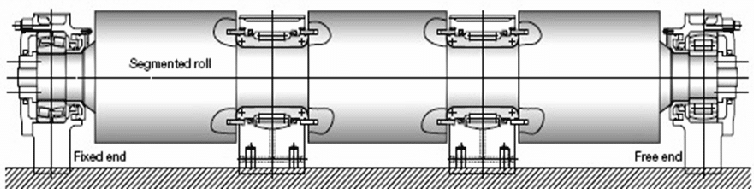

2. Continuous caster segment roll structure

Roll structure development

1. one-piece roll, two bearings

2. one-piece roll, four bearings

3. three pieces of roll, six bearings

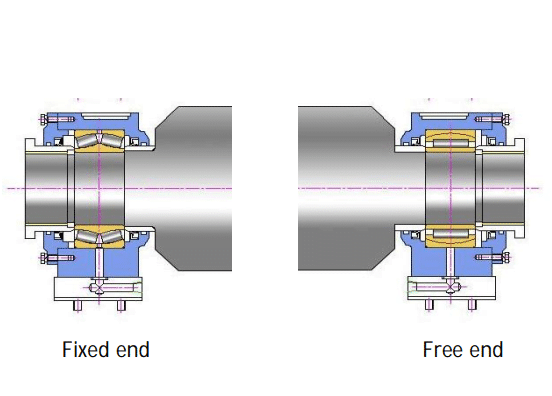

3. Bearing arrangements for segment rolls

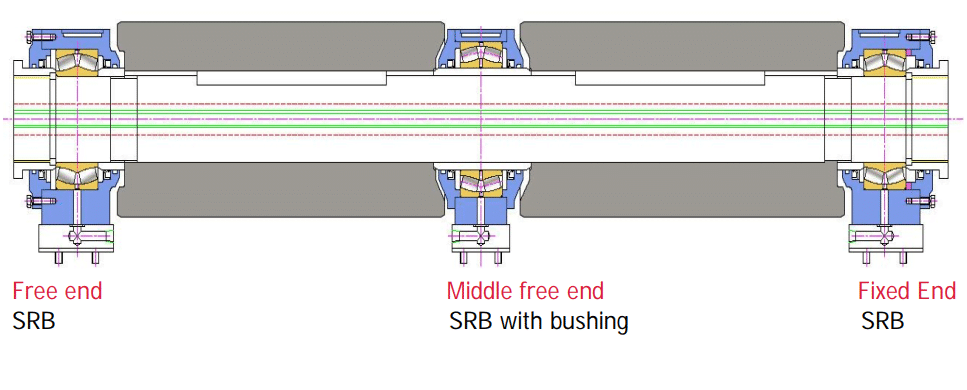

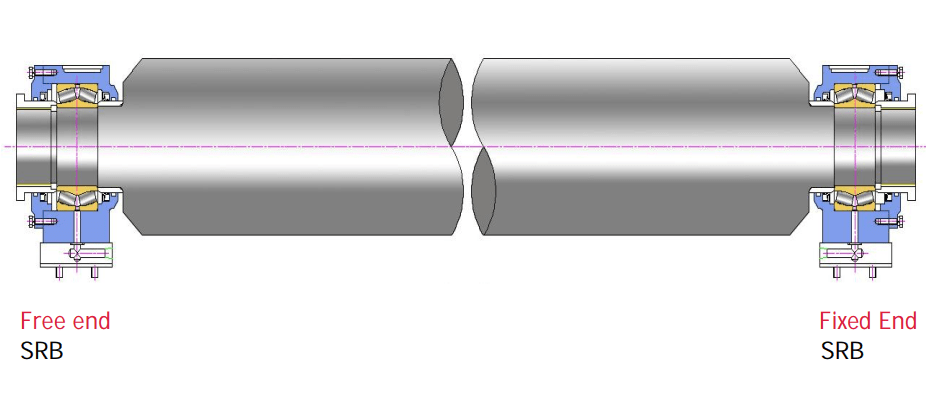

Arrangement 1:

All spherical roller bearings. There is a spherical roller bearing in the middle with a lubricating groove and holes (CA/W33), And there is a bushing inside the inner ring, to let the bearing move axially.

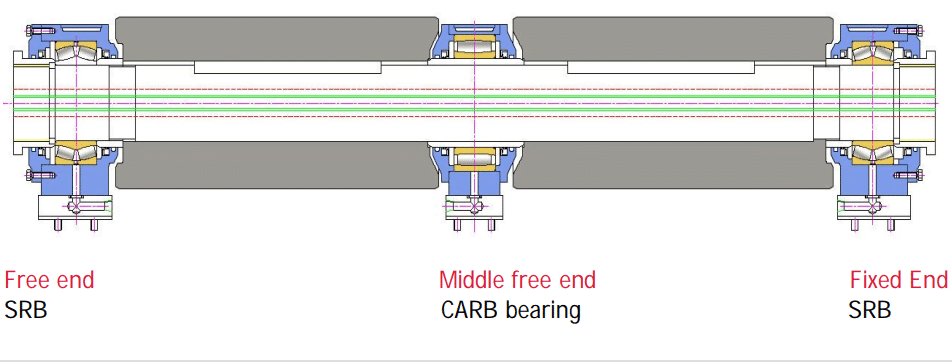

Arrangement 2:

In the middle there is a CARB bearing to replace the floating middle bearing.

Arrangement 3:

There are two spherical roller bearings. The advantage is its interchangeability.

Free end Fixed End

SRB SRB

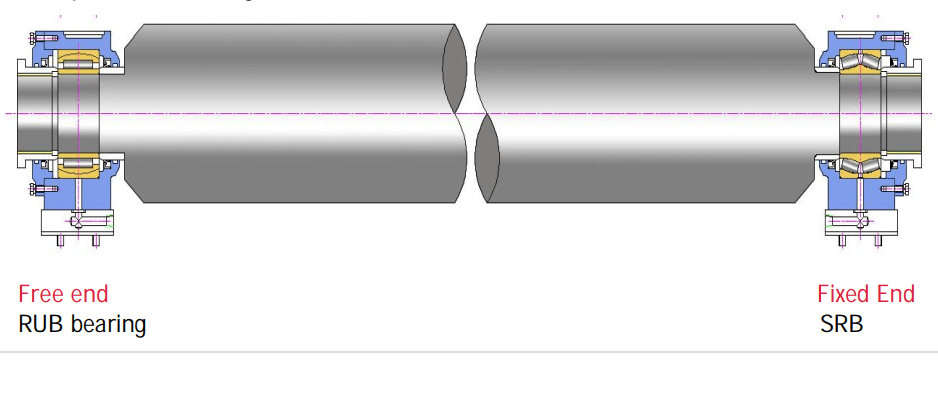

Arrangement 4:

One spherical roller bearing on the fixed end, One RUB bearing on the free end. RUB bearing can accommodate axial displacement misalignment in the same time.

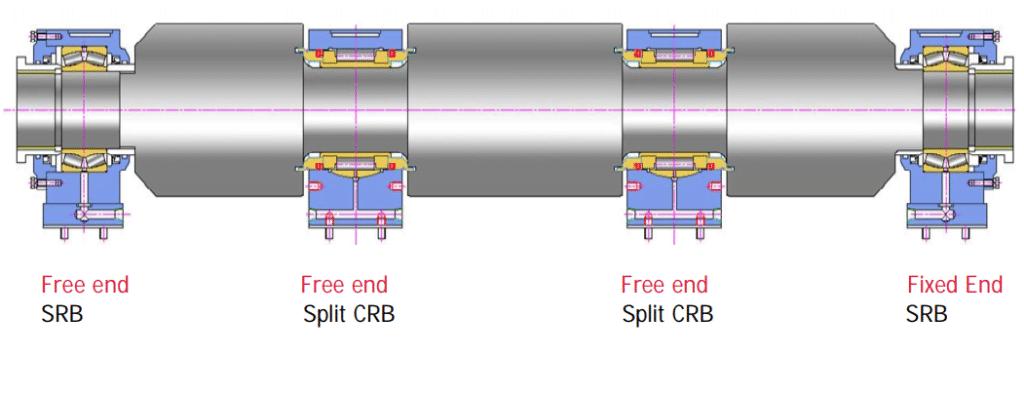

Arrangement 5:

There are two split CRB in the middle of the roll, making load carrying capacity and rigidity of the roll higher,and with the added benefits of facilitating the mounting and dismount of bearings.

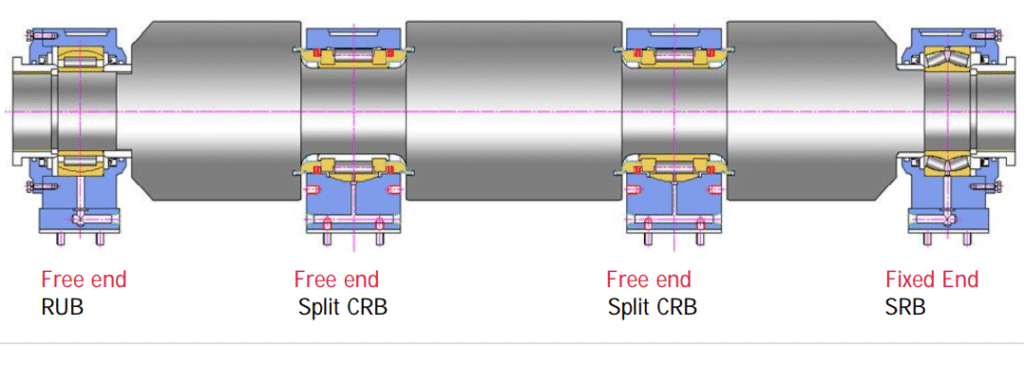

Arrangement 6:

Compared with arrangement 5, there is a RUB bearing in the free end to accommodate axial displacement and misalignment in the same time.

4. Bearings for casting segment rolls

4.1. Characteristics of continuous caster roll bearings

Working conditions:

heavy load, low speed, high temperature, wet, steam, highly contaminated with hammer scales.

Requirement for bearings:

1. Heat resistant,

2. Accommodating axial displacement.

3. Self-aligning

4. Resistant to shock load.

5. Wear resistant, higher service life than roll.

6. Good sealing and lubricating properties.

Clearance choosing:

Narrow slab caster: C3 clearance

Wide slab caster: C4 clearance

Split bearing clearance should be the same with other bearings.

4.2. Bearing types

Working conditions:

The below types of bearings apply to all kinds of roll structure(One piece roll, one piece multi section roll, one piece roll with bushing, multi-section roll): SRB with big clearance, water cooled split bearing with housing, RUB bearing and CARB bearings

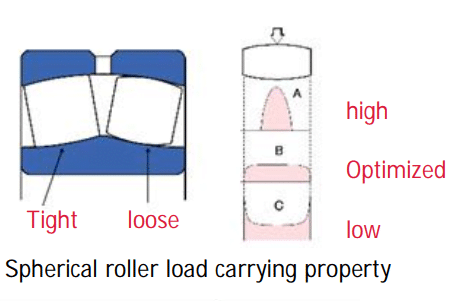

4.3.1. SRB specially designed an manufactured for continuous caster

How are Continuous caster SRB different?

- Reinforced contact surface to make bearings service life longer.

- Optimized friction structure to reduce friction.

- Special internal clearance to accommodate axial displacement.

- Optimized self-aligning property.

- Heat-resistant property.

Features:

- SRB with S1 an S2 suffix

- SRB with C3 and C4 clearance

- SRB with Symmetrical roller and high load carrying capacity.

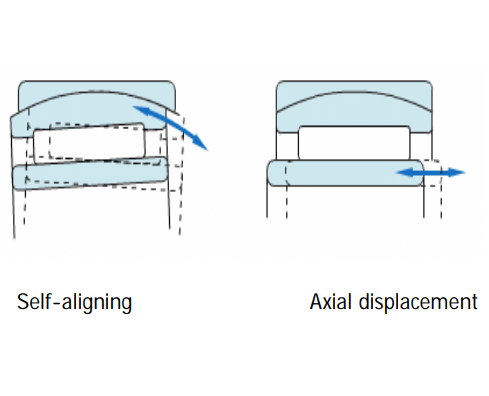

4.3.2. RUB specially designed an manufactured for continuous caster

A new type of cylindrical bearing with outer self-aligning spherical washer.

- Specially designed for free end of continuous caster.

- Accommodate both axial displacement and misalignment

Features:

- Big self alignment angle

- Big clearance

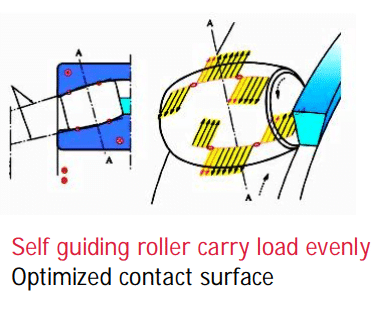

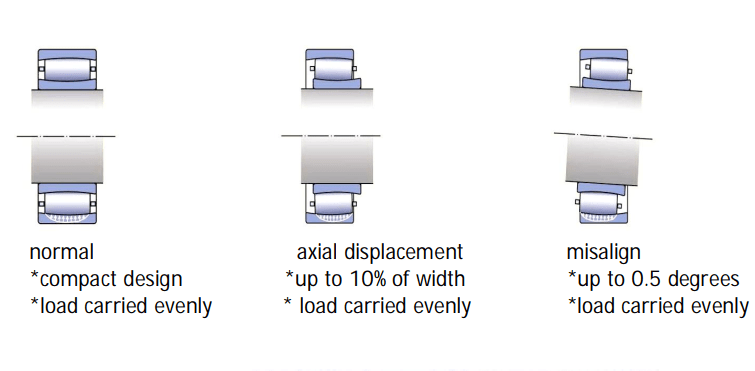

4.3.3. CARB specially designed an manufactured for continuous caster

Special Features of continuous caster CARB bearings

- improved bearing arrangement on long shaft

- self guiding rollers to carry load evenly in displacement and misalignment*

- longer lubricating intervals and longer service life

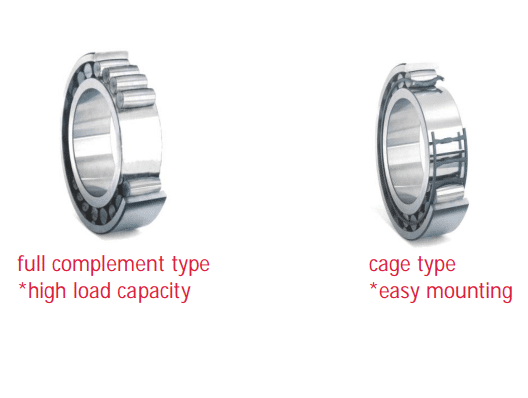

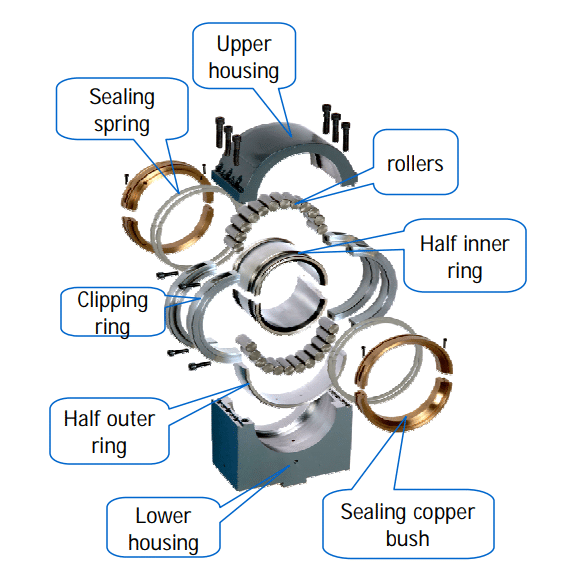

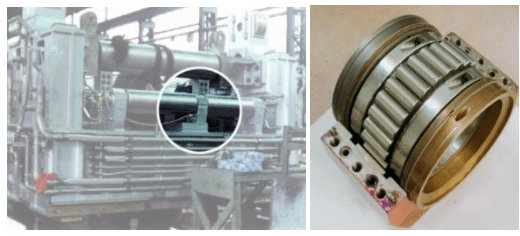

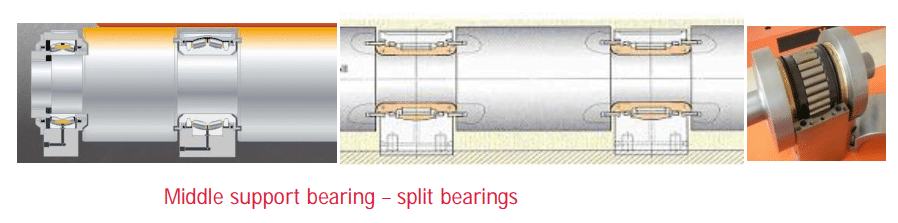

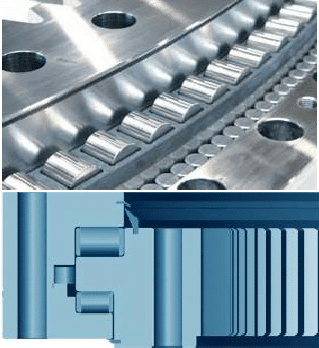

4.3.4. Split bearings

Special Features of continuous caster split bearings

- easy mounting and dismounting, especially for long roll middleparts

- self-aligning ability to accommodate misalignment under heavy load.

- multi labyrinth seal with compact design.

- high rigidity machined bearing housing with water cooling and lubrication holes.

Design features

- load ratio >3.5

- no interference between roll and bearing

- shaft fit e7

- housing fit H7

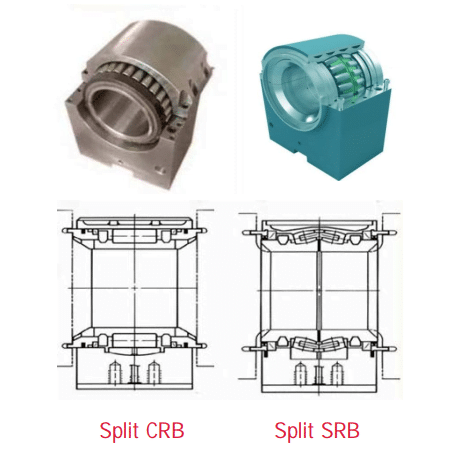

4.3.5. Split Carb and Spherical Roller bearings

Split CARB and Split Spherical roller bearing

- Split cylindrical roller bearing can accommodate axial displacement, misalignment is accommodated by two half housing.

- Split spherical roller bearing can accommodate misalignment axial displacement is accommodated by loose fit of housing.

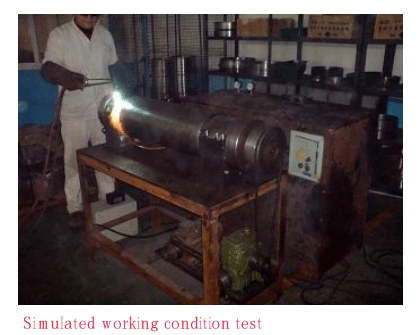

4.3.6. Split bearing unit manufacturing and Quality Control

- Design: material selection according to working environment.

- Manufacturing: CNC machining to ensure precision.

- Assembly: assemble and test before delivery, to check self aligning, center height

- Testing: specially designed testing equipment, to test sealing performance.

- Test condition: cooling water circulation, heat resistant, under 38 Bar pressure without leakage of water and lubricant within 10-15 minutes.

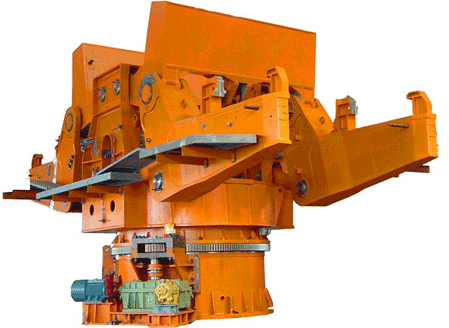

5. Ladle turret bearing

Slewing bearing for ladle turret

Ladle turret normally use three row roller structure slewing bearing, which can take high redial load, axial load and tilting moment in the same time.

In harsh working conditions with high temperatures, dusty, it is very demanding on bearing cage, lubricant, and seal.

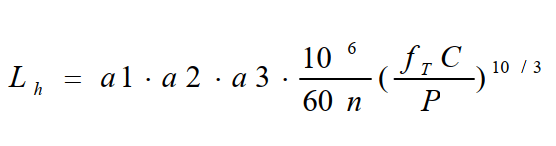

6. Bearing life and mounting

6.1. Service life calculation

Bearing life calculation equation for continuous caster bearings:

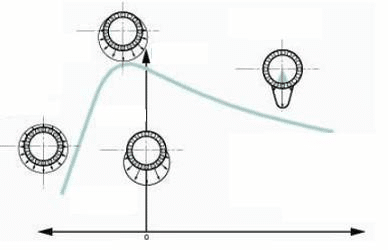

6.2. Clearance choosing

Narrow slab caster: C3 clearance

Wide slab caster: C4 clearance

Split bearing clearance should be the same with other bearings.

Clearance

Too big: lower load capacity, higher stress, lower precision, higher noise, shorter life.

Too small: higher precision, higher temperature, easily lead to seize-up.

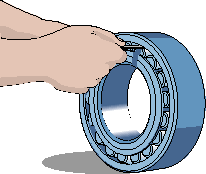

6.3. Mounting fit for bearings

- Most of the continuous caster bearings shall be mounted with a standard fit, namely, tight fit for the rotating ring, loose fit for the stationary ring.

- Special places, e.g. foot bearings under the mould, due to a frequent replacement, loose fit, or transition fit is recommended to facilitate the mounting and dismounting process.

- For middle Spherical Roller Bearing bearings, to compensate length change caused by thermal expansion and extraction, it is recommended that a loose fit for the inner ring is adopted to ensure the bearing moves axially on the shaft.

7. Bearing lubrication

7.1. Lubrication method

Grease; thin oil circulation; oil mist; oil air lubrication.

There are mainly two kinds of lubrication systems.

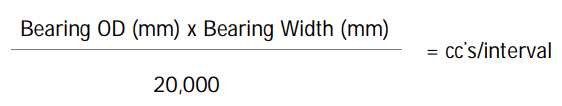

One is central distribution system. The system contains many sub systems. It is characterized by distribute lubricants at regular time with each distribution portion relatively small, Normally less than 5 cc. The time interval is usually 6 to 10 times per hour. It supplies fresh lubricant at such time intervals, and in the meantime take away old grease and contaminants.

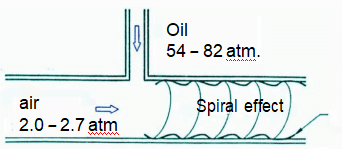

The other system is oil air lubrication system. This system transport lubricant with compressed air, through pipe to the bearings. Bearings are cooled and cleaned while lubricated. It can save lots of lubricants.

7.2. Features

In segment rolls, because bearings are water cooled and contaminated by metal scraps, and carrying high load at very low speed, it is hard to form oil film between rollers and raceway.

In order to facilitate the formation of lubricant film, viscosity class of lubricant must be selected according to working conditions. High viscosity will facilitate the formation of lubricant film, in the meantime prevent water corrosion and help sealing of the bearing.

On the other hand, low viscosity will be easy for pumping. Therefore it is recommended to pump lubricants with set quantity and at set time intervals. Frequently pumping with small quantity is recommended

Note: Even with cooling water, with up to 1000 degrees Celsius slab temperature radiation, the bearing operating Temperature will be up to 150 –200 degrees Celsius. Lubricant service life will be decreased by 50% with every 10-15 degrees Celsius increase.

7.3. Lubricant

Adjust according to experience.

Longest interval is 10 minutes.

7.4. Oil mist lubrication

Oil mist lubrication is more advanced. Nowadays, most of continuous caster use oil mist lubrication system.

Advantages:

- positive pressure inside the bearing will help to seal the bearing and prevent contaminant from coming in.

- lubricating film is formed with high load and low speed.

- bearing is cooled by compressed air.

- grease pollution to cooling water is prevented and process cost is cut down.

- slab casting resistance force is decreased and energy is saved.

8. References

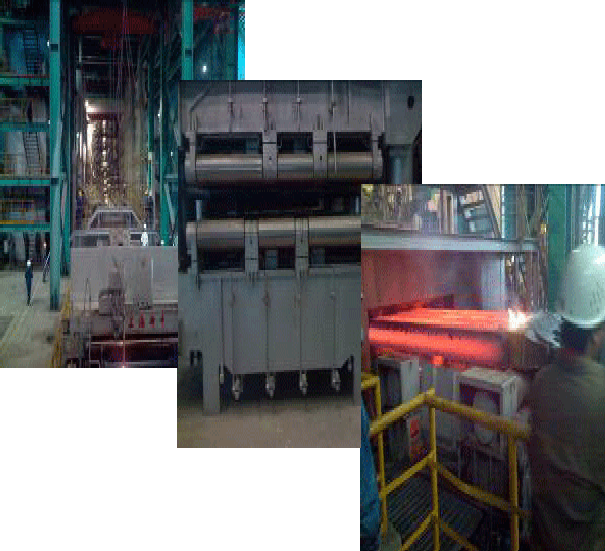

8.1 Many steel factories using our continuous caster bearings

| Factories | Equipment | Parts | Bearing Number |

| Guangdong Baojia Steel | No.3 Plant Continuous Caster | Support Roll | 22324CC/W33/S1/C4 ETC. |

| YONGJIN CORP. | 1# Continuous Caster | Casting Table | 23034C/W33 ETC. |

| YONGJIN CORP. | 1# Continuous Caster | Casting Table | 23126CA/W33 ETC. |

| Zhejiang Jianheng Steel | 1300 Slab Continuous Caster | Conveyor Rolls | 24128CA/C3/W33 ETC. |

| Zhejiang Ruikai Stainless Steel | 3# Slab Continuous Caster | Conveyor Rolls | 23136CC/C3/W33 ETC. |

9. About us

Professional Steel Industry Bearing Solution Provider

Experience is the most important factor in bearing manufacturing.

Not all of the bearing manufacturers know bearing application aswell as we do.

From steel making to steel rolling, our bearing is a good solution for productivity increasing and cost cutting.

In China, we are working with many of the steel companies. YONGJIN CORP., Zhejiang Ruikai Stainless Steel and Zhejiang Jianheng Steel are all our valued customers.

Now with decades of experience in steel mill bearings, we are expanding to the global market with references of MMK – MAGNITOGORSK STEEL, WHEMCO, and Zaporizhstal.

Hope to cooperate with you and provide you with our value.

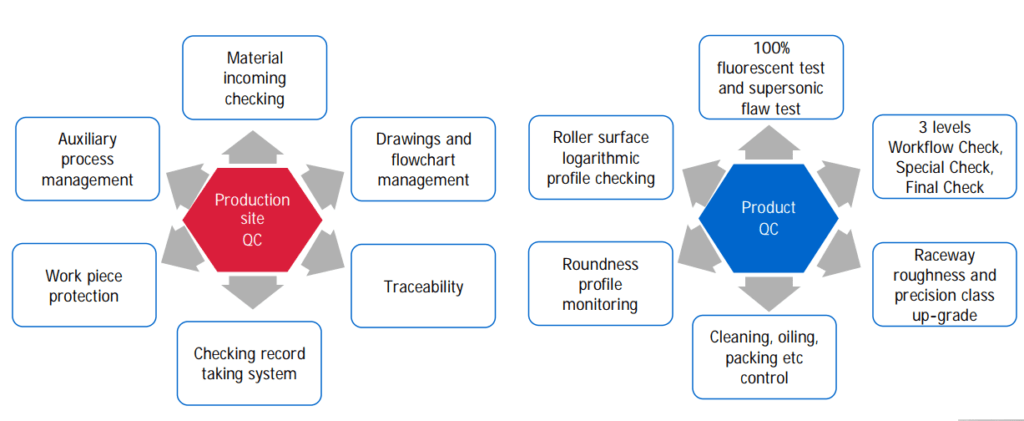

Strict Quality Control System

Total Quality Management is what we have adopted to improve our quality.

Advanced equipment ensures precision.

Strict workflow rules out possibility of flaw products.

Continuous effort in R&D

We have a team of 50 people as our designing engineer and application engineer in the field of steel mill bearings

We allocate 5% of total sales volume in to Research and Development every year.

35% of our total production are newly developed products.

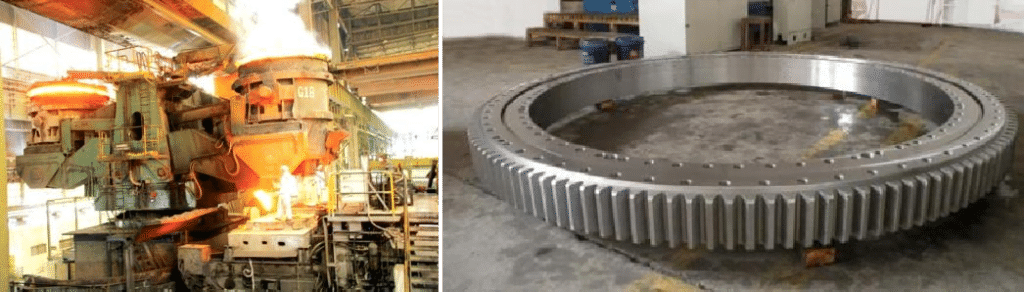

Production

Precision class: P2 (¢200mm≤D≤¢1600mm)

Grinding: over 50 CNC grinding machines

Heat treatment: Bainite salt bath quenching.

Main Products

Ladle turret split and non-split Spherical Roll Bearing

Continuous caster bearings, Spherical Roller Bearing and CARB

Hot rolling and cold rolling mill, roll neck four row CARB Bearing, Taper Roller Bearing and Thrust Bearings

H-shape steel mill double row, four row Taper Roller Bearing, CARB Bearing and screw down taper roller bearings

Sendzimir backup roll bearings

Steel mill cooling bed split bearings

Slewing bearings for heavy machinery

Wind turbine main shaft bearings

Industrial rolling bearings in other applications.

Cement Port machinery Cold rolling Hot rolling Continuous casting Steel making Shaped steel