Ball bearing manufacturer: Quick Guide to Know About Ball Bearings

Ball bearings are widely utilized in various goods and applications, making them the most common form of bearing. Ball bearings are used in everything from hard disks to skateboards to withstand thrust and radial stresses. On the other hand, ball bearings are more often used in situations with lower pressures. Before looking at ball bearing manufacturers, it is essential to know what they are all about. In this article, we will help you gather the knowledge you require about ball bearings.

What exactly are ball bearings?

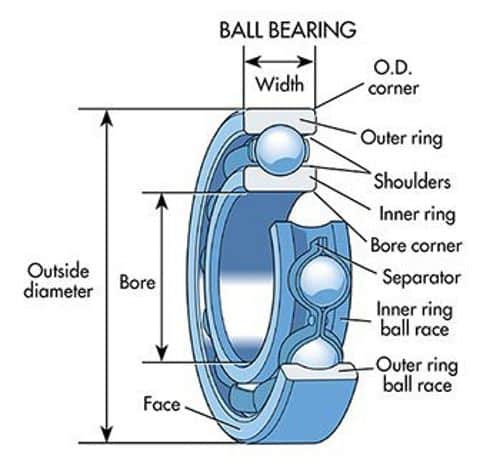

Bearings employ an actual construction to perform all of these functions: a ball with smooth metal surfaces on the inside and outside to help in rolling. The load carried by the ball drives the bearing’s rotation. Nevertheless, not all loads exert the same strain on a bearing. Radial and axial loading are two types of loading.

When the bearing rolls or rotates when tension is applied to a bearing through a pulley or other radial load, on the other hand, a thrust load is very different and places wholly new demands on the bearing. A thrust load happens when a bearing (like a tire) gets slammed on its side and subjected to a lot of force because of its angle. In the case of a bar stool, a thrust load is required for a bearing.

Through this mechanism, ball bearings can transmit a load from one side of a bearing to another. The spherical form of the ball only contacts the inlet and outlet race at highly remote locations, allowing everything to spin smoothly. However, if the bearings are not utilized correctly, this might be a barrier. The balls can get distorted if the bearing is overworked because of the narrow contact area.

Car wheels, engines, and turbine to hospital devices utilize rolling-element bearings to guarantee smooth and effective functioning. A ball bearing is a rolling-element bearing that bears loads, lowers friction, and positions moving machine elements while facilitating motion. The best ball bearing manufacturers offer ball bearings to suit all these applications.

Using balls to divide two “races,” or bearing rings, ball bearings help minimize the amount of contacting surfaces and friction on moving planes. Compared to two flat surfaces grinding against each other, the rotating balls have a lower coefficient of friction. Ball bearings usually have a lower maximum load for their size than some other rolling-element bearings because there is less contact between both the balls and races.

Many goods and applications employ ball bearings from reputed ball bearing manufacturers because they have proven practical and straightforward to produce. Things like blenders and gym equipment use ball bearings regularly. There are many examples. Ball bearings are used in a wide range of everyday items, including bicycles, water pumps, DVD Players, washing machines, and fans.

Additionally, ball bearings may be found in many high-tech applications. Ball bearings, for example, are used in the Mars Rover, the Hubble Telescope, and weather satellites.

What is the characteristic of different ball bearing types?

There are multiple types of ball bearings available for you to get. Let’s take a look at the most prominent options and their characteristics.

– Deep groove ball bearing

Because of their adaptability and overall performance, deep groove ball bearings are the most often used roller type globally. These raceways’ inlet and outlet rings feature circular arcs with a bigger radius than the ball’s radii. Non-separable rings adorn their fingers as well.

– Angular contact ball bearings

This kind of bearing can handle high radial-axial loads and fast speeds, making it ideal for applications that need both. For manufacturing reasons, they are asymmetrical and can only resist axial stresses in one direction. They’re commonly installed in groups of two or more preloaded units, each one supported by an elongated or flexible spacer between them.

– Self-aligning ball bearings

Self-aligning ball bearing, the inner and outer rings each have two raceways, and the inner racetrack is aligned with the load-carrying axis. Because of this, any misalignment in the housing or shaft caused by the machining or incorrect installation of the bearing housing and shaft may be immediately corrected.

What is the precision grade of ball bearings?

The Annular Bearing Engineering Committee came up with a rating system, which is now being used as the industrial standard for determining the tolerance levels of roller bearings. According to that standard, there are five different tolerance classes in there.

So, according to the tolerance, there are 5 classes of ball bearings. They are P0, P6, P5, P4, P2. Out of these, the tolerance of P0 is the widest one, whereas the tolerance of p2 is the tightest one. If the tolerance class is tight, it means that the bearings are capable of offering a higher precision.

Bearings that come along with a higher precision also contain a higher accuracy. On the other hand, they have a higher potential to accommodate different industrial applications, which require you to use very high speeds. However, a higher precision class doesn’t mean that the bearing is capable of carrying a high load.

Why should you buy ball bearings from EVERGLORY?

Now you know what ball bearings are all about. That’s where you should focus on the significant ball bearing manufacturers out there. As you go through different ball bearing manufacturers, you will come across EVERGLORY. It is an 18-year old top ball bearing manufacturers that know the ins and outs of offering the highest quality ball bearings. Therefore, you can keep peace of mind and get ball bearings that are available for your purchase in the market.

As one of the leading ball bearing manufacturers, as well as roller bearing manufacturers EVERGLORY offers all sorts of ball bearings. You can even them at an affordable price as EVERGLORY is the manufacturer itself. On top of that, you can expect to receive a quality service from them like any other ball bearing manufacturers usa at all times.